About Us

Ciesse is a company specialized in the production of high-precision complex mechanical

components, manufactured with the synergy of additive technologies and machining techniques

(milling, turning, EDM). For over 30 years, we have been operating in sectors such as racing,

automotive, medical, aerospace, aviation and molds.

Our Services

Customized products, conformity to the quality standard ISO 9001, experience with the most

advanced technologies in manufacturing since 1978: these are some of the key success factors

that Ciesse cultivated over the years to build its strong brand in the market. Always looking at

customer satisfaction as the ultimate goal.

Have already chosen ciesse

A Prosthesis for partial hand amputation

A hand exoskeleton for rehabilitation

Main Fields of Application

Racing e Automotive

Since the Nineties, Ciesse has been supplying components for Formula 1™ and more specifically for Ferrari Gestione Sportiva. If you want to discover more about the products manufactured for the racing sector follow the link.

Molds

The company manufactures molds with conformal cooling using the powder-bed metal fusion technology. The ability to build internal channels is one of the competitive advantages of additive

manufacturing.

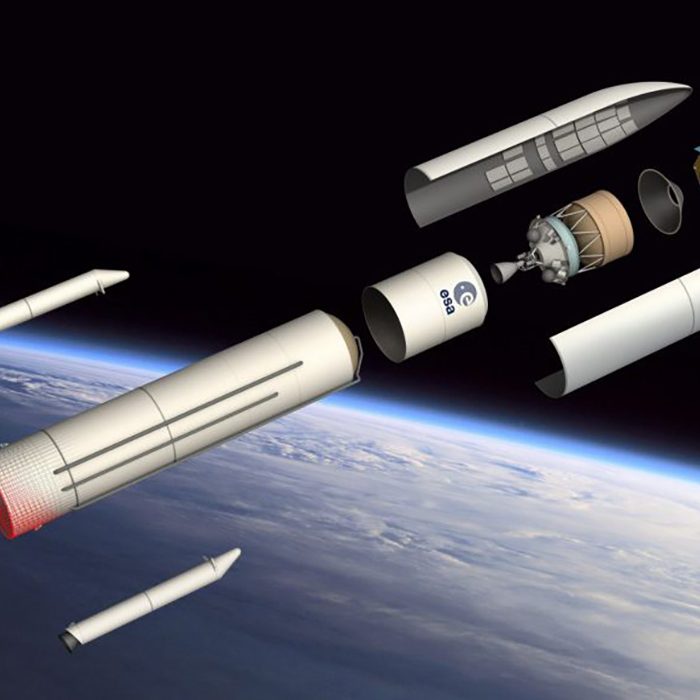

Aerospace and Defence

For the aerospace and defense sectors, Ciesse produces prototypes and small series, mostly with

additive technologies, with the creation of complex geometries that allow for the optimization of the

performance.

Aviation

Ciesse has been working for the commercial aviation sector for several years now with serial

productions manufactured both completely through machining and through secondary machining operations on components manufactured through Metal Injection Molding.

Our Services

Additive Manufacturing

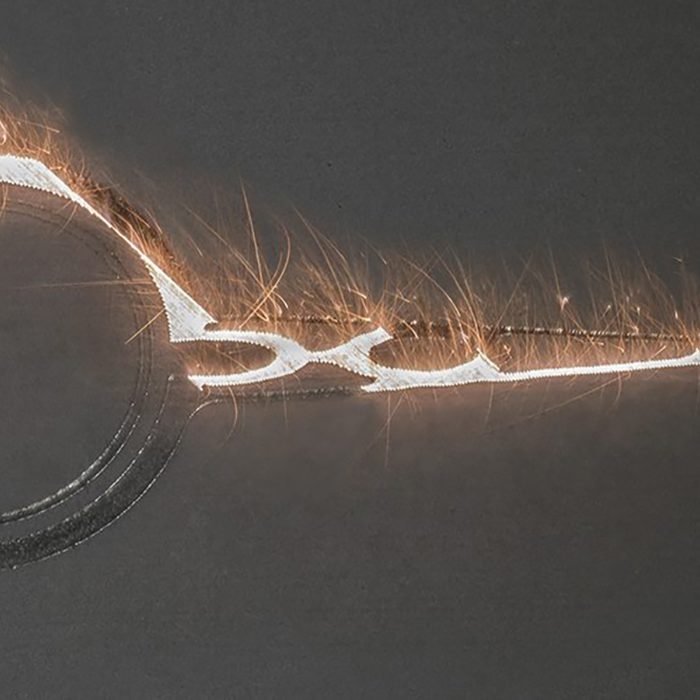

Powder-bed fusion laser melting is an additive manufacturing process that allows for the

manufacturing of complex metal components directly from a 3D file. First, the 3D file is elaborated

through specialized software and supports necessary for the build process and easy to be

removed in the post-production phase are added.

Machining

The combination of additive manufacturing and machining techniques is one of the most advanced technological mix to produce high-precision mechanical components. Ciesse milling, turning, electro-discharge machining departments allow, one side, to manufacture series of components totally produced through chip removal; on the other side, the same departments allow performing the necessary secondary operations on raw components manufactured by additive manufacturing.

Quality Control

Ciesse testing department has three main objectives: to verify that supplied materials (raw or semi-finished) comply with quality standards; to support departments involved in the production process of mechanical components and to test finished parts, providing all certifications that a given client requires.

3D Modeling

DfAM – Design for Additive Manufacturing (DfAM) is one of the most interesting frontiers, because it allows rethinking the design phase as to optimize all the advantages offered by the powder-bed laser melting (ex. light weighting)

Latest news