The synergy of machining techniques and Laser Melting is one of the most appreciated mix by Ciesse target markets. Once the unrefined component is obtained, machining techniques allow for greater accuracy and compliance where dimensional tolerances are involved, requiring fewer operations. Since its inception, Ciesse has been devoted to and invested into technological innovation, integrating, at all stages of production, the highest performing machinery available on the market for its milling, turning, EDM departments.

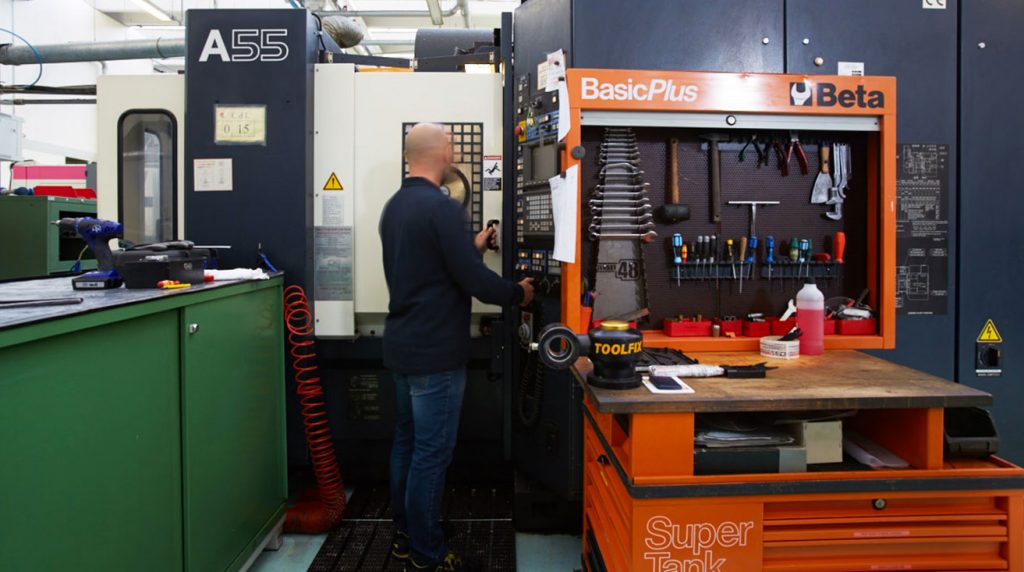

Milling

The milling is a process of metal-removing by feeding the workpiece passes through the rotating multipoint cutter. This machine can hold one or more number of cutters at a time and rotates at high speed to remove the metal at a faster rate.

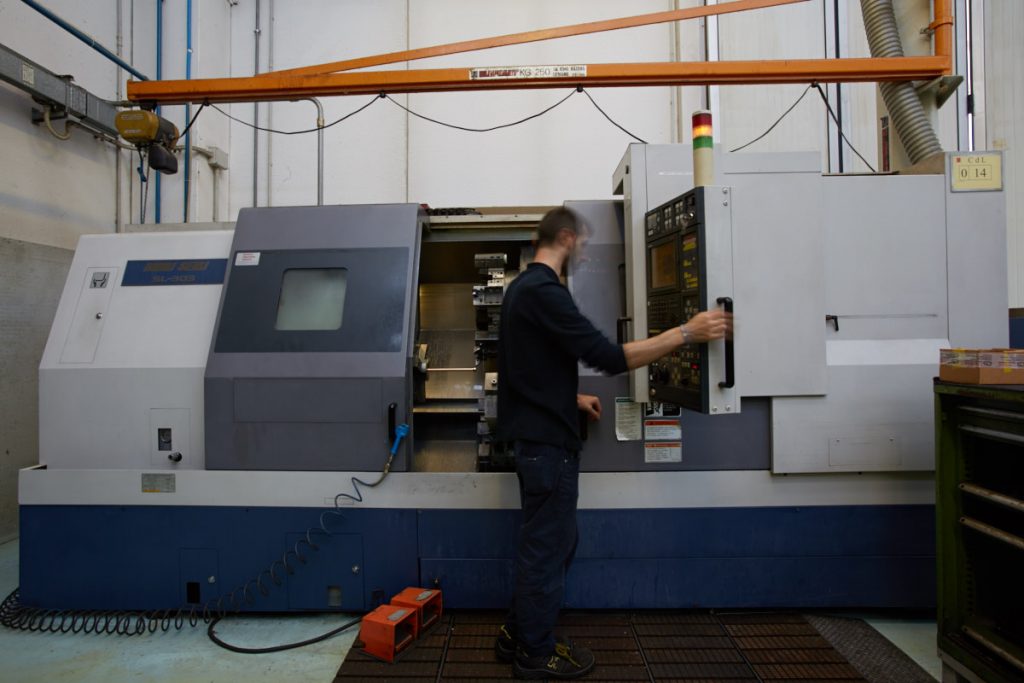

Turning

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates

EDM

Electrical Discharge Machining is the process of metal removal from the work surface due to an erosion of metal caused by electric spark discharge between the two electrodes tool (cathode) and the work (Anode).

Marking

Ciesse at RM Forum 2021, the conference dedicated to the Italian additive manufacturing ecosystem

Ciesse celebrates 13 years of additive manufacturing

Main Fields of Application

Racing e Automotive

Since the Nineties, Ciesse has been supplying components for Formula 1™ and more specifically for Ferrari Gestione Sportiva. If you want to discover more about the products manufactured for the racing sector follow the link.

Molds

The company manufactures molds with conformal cooling using the powder-bed metal fusion technology. The ability to build internal channels is one of the competitive advantages of additive

manufacturing.

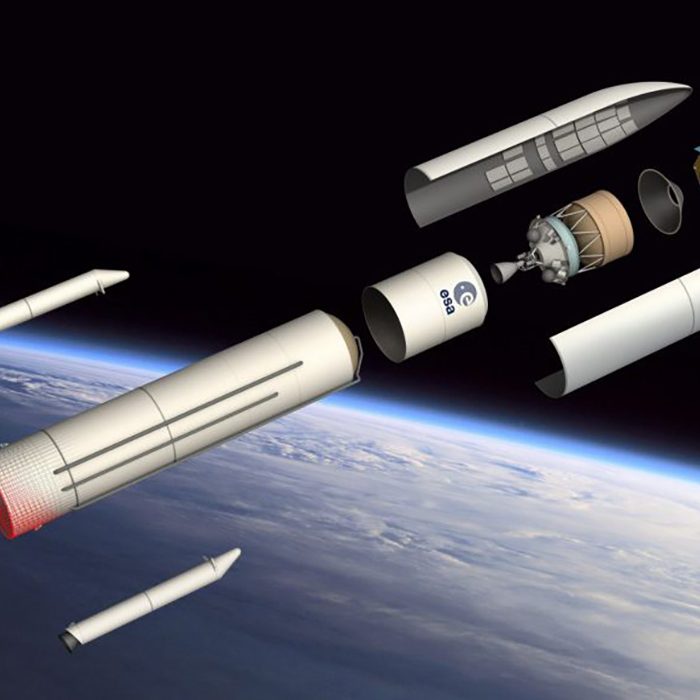

Aerospace and Defence

For the aerospace and defense sectors, Ciesse produces prototypes and small series, mostly with

additive technologies, with the creation of complex geometries that allow for the optimization of the

performance.

Aviation

Ciesse has been working for the commercial aviation sector for several years now with serial

productions manufactured both completely through machining and through secondary machining operations on components manufactured through Metal Injection Molding.