The testing department has three main objectives: to verify that supplied materials (raw or semi-finished) comply with quality standards; to support departments involved in the production process of mechanical components and to test finished parts, providing all certifications that a given client requires. Along with the department for dimensional controls which counts around 1,400 instruments, Ciesse has installed a metallurgical laboratory, supplying the company’s additive manufacturing department with important information or findings as well as guaranteeing all necessary metallurgic certifications upon product delivery.

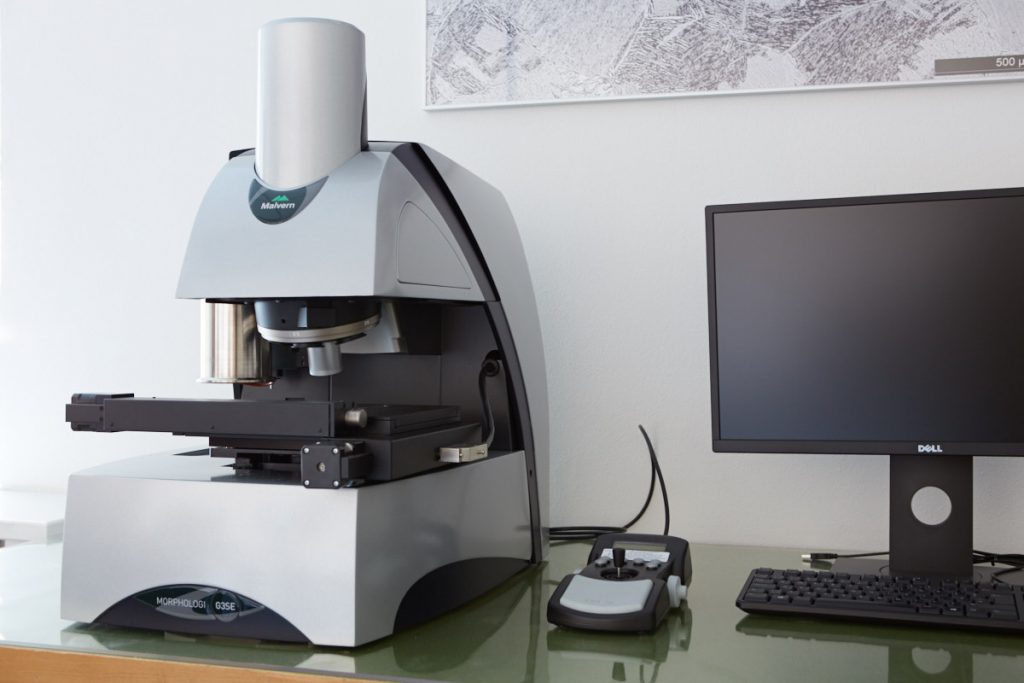

Metallurgic Lab

Ciesse samples e monitors the lots of powder, when received by external suppliers, and during the production process (e.g. after the sieving cycles) as to guarantee the conformity to standards (ASTM e ISO) and to customers’ specifications.

The key parameters are:

MORPHOLOGY | GRANULOMETRIC DISTRIBUTION | POWDER FLOW | OPTICAL MICROSCOPY

The objective of sampling and re-sampling activities is to define a control plan for raw materials which defines, for each relevant parameter, ranges of acceptable values e which allows defining the internal procedures for powder handling.

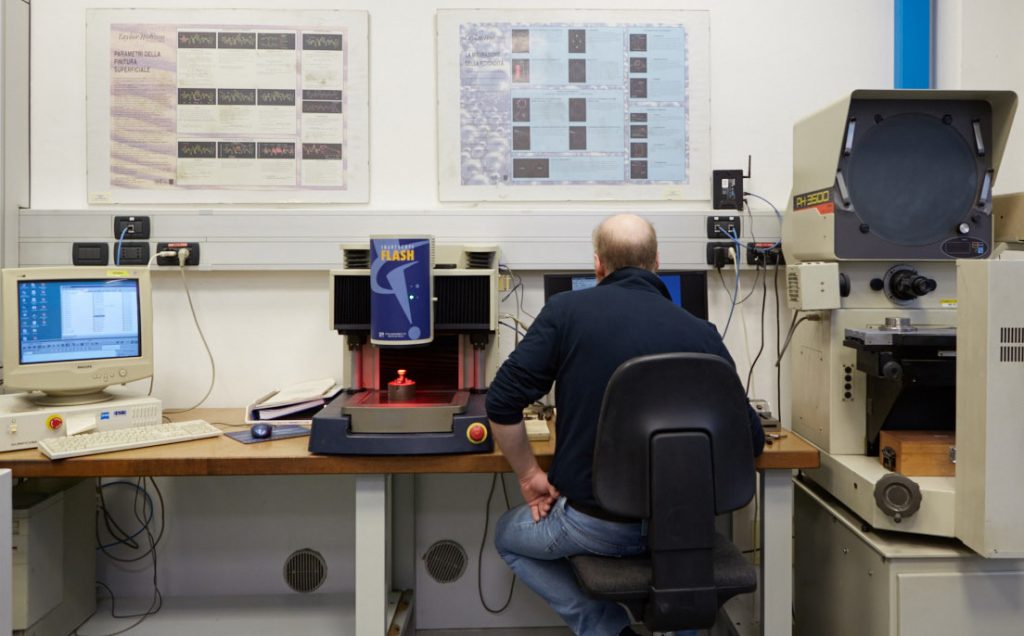

Dimensional Control

Coordinate measuring machines (CMM) offer high precision and reliability in the phase of dimensional control of components produced in additive manufacturing or with traditional machining or with a combination of both. Ciesse invested in automated metrology solutions to offer to its clients an optimized quality control service for the post-processing dimensional measurement, thus guaranteeing compliance to the project specifications. Our machine fleet counts, among others, 1 DEA Global Image Clima, 1 DEA Performance, 1 DEA Tigo (Hexagon Metrology).

Ciesse at RM Forum 2021, the conference dedicated to the Italian additive manufacturing ecosystem

Ciesse celebrates 13 years of additive manufacturing

Main Fields of Application

Racing e Automotive

Since the Nineties, Ciesse has been supplying components for Formula 1™ and more specifically for Ferrari Gestione Sportiva. If you want to discover more about the products manufactured for the racing sector follow the link.

Molds

The company manufactures molds with conformal cooling using the powder-bed metal fusion technology. The ability to build internal channels is one of the competitive advantages of additive

manufacturing.

Aerospace and Defence

For the aerospace and defense sectors, Ciesse produces prototypes and small series, mostly with

additive technologies, with the creation of complex geometries that allow for the optimization of the

performance.

Aviation

Ciesse has been working for the commercial aviation sector for several years now with serial

productions manufactured both completely through machining and through secondary machining operations on components manufactured through Metal Injection Molding.